BarChip macro synthetic fibre helps Parramatta Light Rail deliver world-class sustainable infrastructure, reducing the carbon footprint by 4,815 tonnes of CO2e, reducing labour costs by 15% and helping Parramatta Connect achieve the highest ever ‘As-Built’ IS score from the Infrastructure Sustainability Council.

At the western end of Sydney Harbour, on the banks of Parramatta River sits the City of Parramatta. Parramatta is one of the largest regions by population in Sydney and is expected to nearly double by 2040 to over 460,000 residents.

To serve the needs of this growing area, the $2.875 billion Parramatta Light Rail (PLR) is being built. Stage 1 of the program includes a 12 km two-way light rail track and supporting works. 16 new light rail stops are being constructed, connecting the line with high-value precincts and forward transport hubs. It is scheduled to open in 2024.

Parramatta Connect, a 50:50 joint venture between Downer and CPB Contractors was awarded the contract to deliver the Infrastructure Package of works for PLR Stage 1. From the very beginning, they were committed to Sydney’s guiding infrastructure principles - Liveability, Productivity and Sustainability. CPB Sustainability Manager Deborah Romero explains;

“Sustainability was a key focus for CPB Contractors and Downer throughout the tender process, with multiple sustainability initiatives embedded very early on. These initiatives included the use of macro synthetic fibres within the track slab to replace steel reinforcement, which was realised throughout the design and delivery of the light rail.”

The design team focused heavily on the social and environmental outcomes of the project.

This included:

- Replacing steel reinforcement in the track slab with BarChip macro synthetic fibre – a NSW first.

- Using a rail boot system design to minimise noise and vibration – an Australian first.

- Laying 1.3 km of ’Green Track‘ to reduce concrete usage and promote urban green space – a NSW first.

- Installing 3.7 km of wire-free track sections with Light Rail Vehicles using batteries.

- Using low-carbon lean-mix concrete wherever possible.

- Building exclusive pedestrian shared space zones in retail locations.

- Using 6000+ tonnes of recycled asphalt and 1000+ tonnes of recycled glass.

- Re-using 95%+ of removed topsoil in supporting landscape works.

- Recycling 99% of waste, diverting more than 145,900 tonnes of landfill.

- Re-using more than 15,000 m of rail, 13,650 rail sleepers and 13,000 m of overhead wires.

|

|

The approach was rewarded with a ‘Leading’ award for the Design and As-Built Rating for the Infrastructure Package of PLR Stage 1 by the Infrastructure Sustainability Council. The project team also realised strong social outcomes with a local first supply goal, more than 50% of the workforce in apprentice or learning roles, 2.6% of women in non-traditional roles and Indigenous procurement targets exceeded by nearly $7 million.

BarChip Fibre Reinforced Concrete Track Slab

Concrete track slab is a rail design method that uses concrete for the rail base as opposed to traditional rail sleepers and ballast. The design is increasingly used as an alternative to ballasted track systems and has become commonplace in light rail construction.

The Parramatta Light Rail has a 100-year design life and was originally specified with a steel reinforced concrete track slab. The opportunity for improved sustainability outcomes, better durability and reduced costs led the project team to consider an alternative design with BarChip fibre reinforced concrete.

The primary design of the Parramatta Light Rail comprised a lean-mix low-carbon concrete sub-base, on top of which the track rails were pre-installed. Following this, the rail is encapsulated with a second layer of concrete.

Traditionally, steel bar reinforcement is used to reinforce this encapsulation layer. However, this process is hugely time-consuming and presents logistical problems from placing bars at close centres in such a confined environment. Steel bars can also cause unwanted conductivity from the rail, potentially causing corrosion of steel infrastructure which negatively impacts design life.

|

|

Using BarChip macro synthetic fibre as a replacement for steel bar eliminated any risk of corrosion, reduced the risk of stray current affecting the steel reinforcement within the track slab and enabled a more efficient construction process. By removing the need to install steel reinforcement in the track slab, Parramatta Connect was able to reduce labour costs by approximately 15% and significantly reduce overall construction time.

The use of BarChip macro synthetic fibre also improves the performance of the concrete with benefits such as increased impact resistance, ductility (concrete toughness), overall durability and flexural capacity. BarChip macro synthetic fibres begin activating at the microcracking stage, reducing crack propagation and minimising crack widths which can improve the quality and durability of the track slab.

|

|

Environmental Outcomes

BarChip significantly reduces the volume of steel required in track slab construction, reduces lifetime maintenance costs by eliminating the risk of corrosion and improves concrete durability. These benefits deliver immediate and ongoing carbon savings to the project and support the 100-year design life.

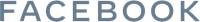

Parramatta Light Rail selected BarChip R50 macro synthetic fibre. R50 is popular in global markets due to its high performance, easy mixing and finishing qualities, and because it’s manufactured with recycled and repurposed plastics. BarChip R50 is supported by a fully verified Environmental Product Declaration (EPD), allowing

accurate determination of embodied CO2e savings that were achieved through the BarChip reinforced design. Deborah Romero explains:

“The project poured over 20,000 m3 of concrete with 101 tonnes of BarChip R50, which reduced the quantity of steel reinforcement required within the track slab structure by 2,426 tonnes. The availability of the EPD by BarChip allowed the project to accurately quantify the embodied carbon of the fibre and conclude that the initiative equated to a GHG emission reduction of 4815.83 tonnes of CO2e specifically due to the removal of steel reinforcement. Overall, this contributed to a State First Innovation for the project contributing 1 ISC Innovation point and contributed to the overall achievement of a 28% reduction in embodied carbon emissions in materials use.”

Using BarChip supports environmental outcomes beyond direct carbon reductions. BarChip is delivered ready-mixed within the concrete, eliminating the need to transport steel reinforcement which further reduced carbon emissions by ~4 tonnes of CO2e. Compared to the original design, the use of BarChip within the track slab reduced freshwater consumption in material manufacturing by over 96% and reduced non-renewable energy consumption by over 86%. BarChip is also provided in recycled paper bags which are used in their entirety within the concrete mixing process, minimising the packaging waste of the product.

BarChip also helped reduce overall construction time which in turn led to an improved social outcome through reduced disruption in the local community.

Conclusions

There are numerous academic papers highlighting the performance, economic and durability benefits of fibre reinforced concrete when compared to steel bar reinforcement, however,

there is little published on the sustainability benefits. On this project, the sustainability-led approach of Downer and CPB Contractors has proven that BarChip fibre reinforced track slab can have significant sustainability benefits as well.

On the Parramatta Light Rail Stage 1 Infrastructure Works, BarChip fibre reinforced concrete enabled a significant carbon reduction compared to the original design. It helped reduce construction time and impact on the community, reduced material transport to the site and made work easier and safer for the construction teams. It also reduced material and resource consumption in the supply chain.

BarChip, combined with a holistic approach to sustainable project design and delivery, helped Parramatta Connect achieve a recordbreaking “As-Built” IS score from the Infrastructure Sustainability Council, and win the 2022 Australasian Rail Industry Infrastructure Project Excellence Award.