Description

DESOI Anchor Stocking System - certified system

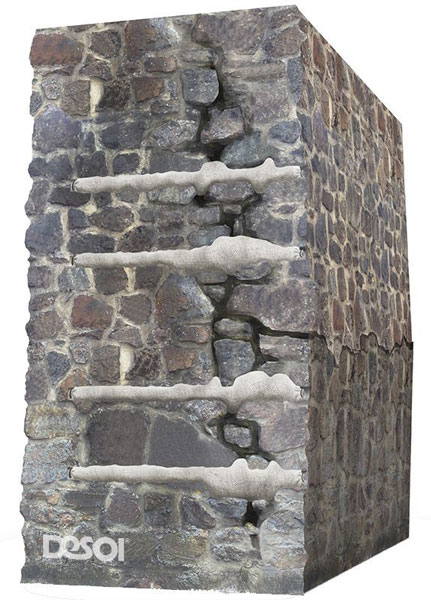

In order to provide planners and executing companies with reliable anchor systems, DESOI GmbH had the bond strength and anchor resistance especially for the anchor stocking system tested and documented by independent and accredited materials testing bodies. The aim of the tests made, was to evaluate the influence of the anchor stocking on the bond behaviour between injection mortar and masonry. Here, the unfavourable case of a borehole with smooth inside surface and the injection mortar was examined. Moreover, practical recommendations should be developed. The bond examinations made, have shown that with the DESOI AnchorNox® dry mortar a good bond strength (medium > 1.5 N/mm2) with minimum slippage (< 0,1 mm) is achieved.

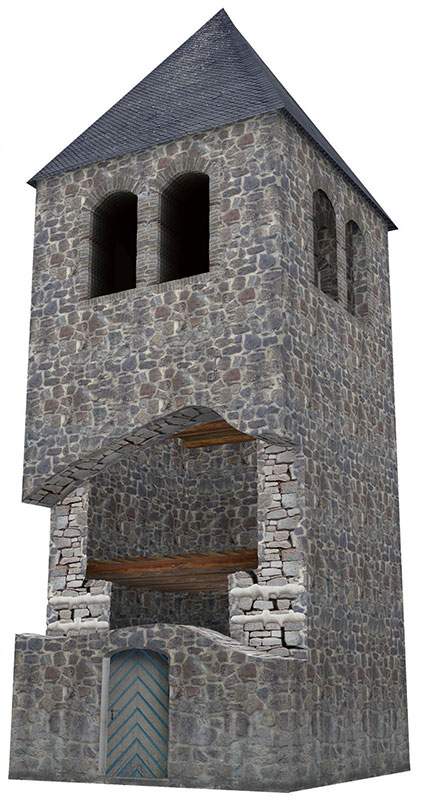

The anchor stocking system is ideally suited for the gentle restoration of listed buildings.

Information: Prior to starting the repair works using anchor systems, the cause of damage needs to be explored and rectified, if possible. According to experience, an instable ground (soil / base) is one of the most frequent causes.

Test report

Materials Testing Laboratory Neuwied GmbH, “Examinations on the DESOI Anchor Stocking System for Securing Historic Masonry Constructions”, no. 6-21/1938b/12, 10 January 2014

DESOI AnchorNox® dry mortar

Interim report, F. A. Finger Institute for Building Materials Science, Professorship for Polymer Materials, “Recipe Adaption and Optimisation of Fresh and Cured Mortar Properties of the pre-mixed Mortar DESOI AnchorNox® for Anchor Stocking Systems”, FIBAN 040-14, 13 March 2015. More tested dry mortars on demand.

The use of the DESOI Anchor stocking system is uncomplicated: Push the spacers on the anchor rod, add the material hose for filling in the anchor mortar and fix the 3 pieces using some crepe adhesive tape. Cut the anchor stocking to the required length and close it on one side with a cable strap. Now slip the textile hose over the anchor package as a stocking and fix it again with a cable strap. Information: Factory-made available as well After the expert installation of the anchor, the filling is carried out. Here, the anchor stocking prevents the filling material from flowing into hollows, rock pockets, etc. Due to the limited amount of material, the building is not unnecessarily loaded. Due to its elasticity, the anchor stocking fits to the irregularities of the borehole. At the same time, the textile structure is permeable enough to grant the bond of the anchor within the structural element.

Information: The professional installation should be planned by a competent planner or engineer.

Tasks and application examples

|

|