Description

REINFORCED CONCRETE BEAM

|

The Problem:The beam has deficiencies in longitudinal flexural reinforcement caused by a change in load conditions The Solution:

|

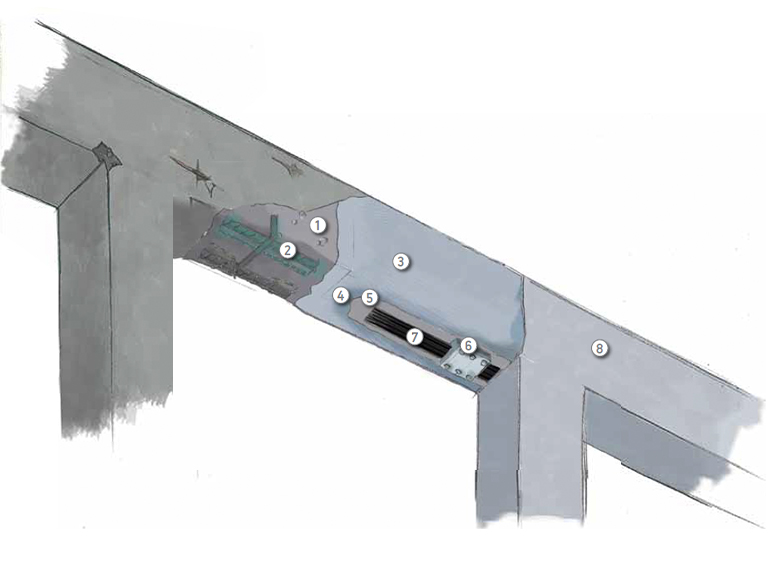

The Problem:The beam has deficiencies in longitudinal flexural reinforcement caused by a change in load conditions

The Solution:

|

|

|---|---|

|

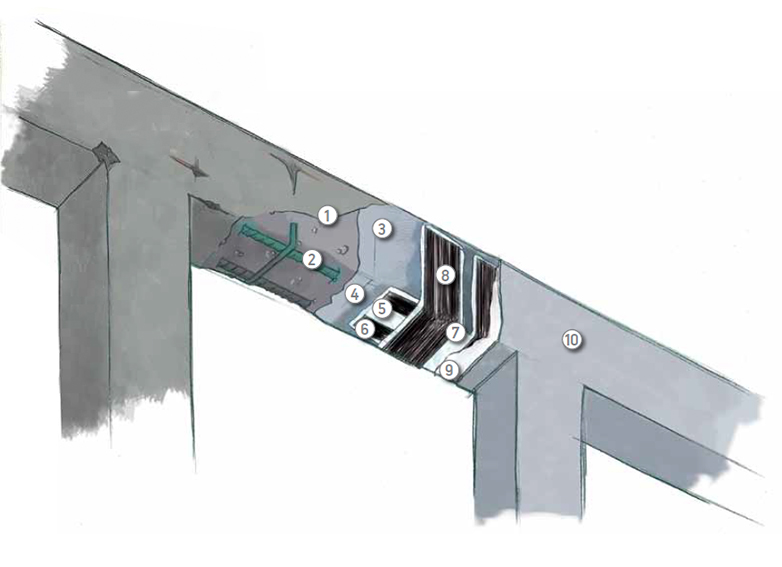

The Problem:The beam has deficiencies in shear reinforcement (stirrups) caused by a change in load conditions or The Solution:

|

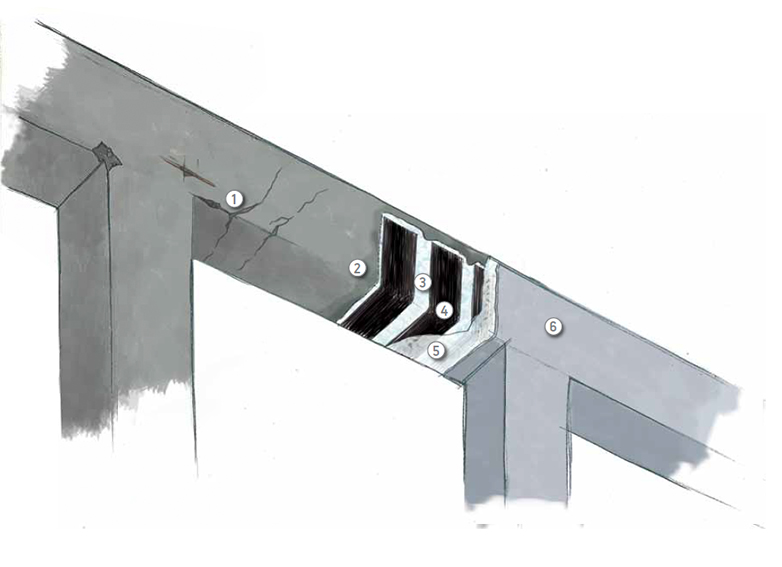

The Problem:Degradation and deterioration of the beam caused by a change in load conditions or by a degradation

The Solution:

|

|

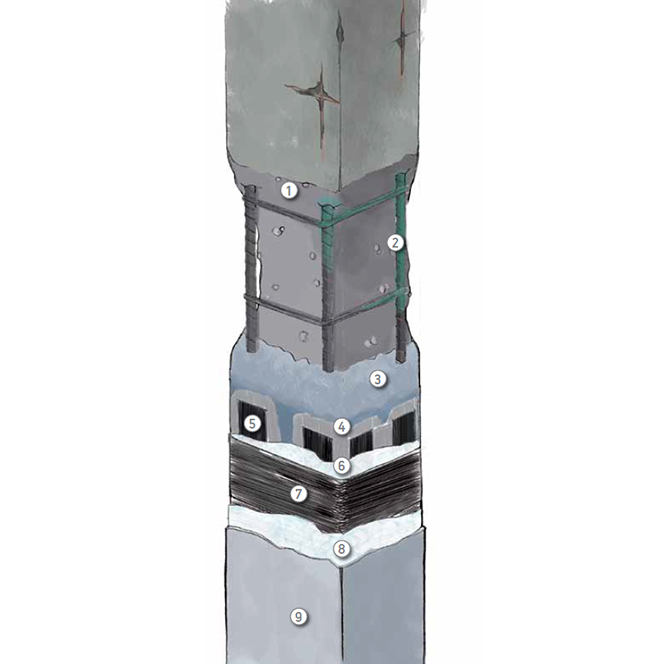

REINFORCED CONCRETE PILLAR

|

|

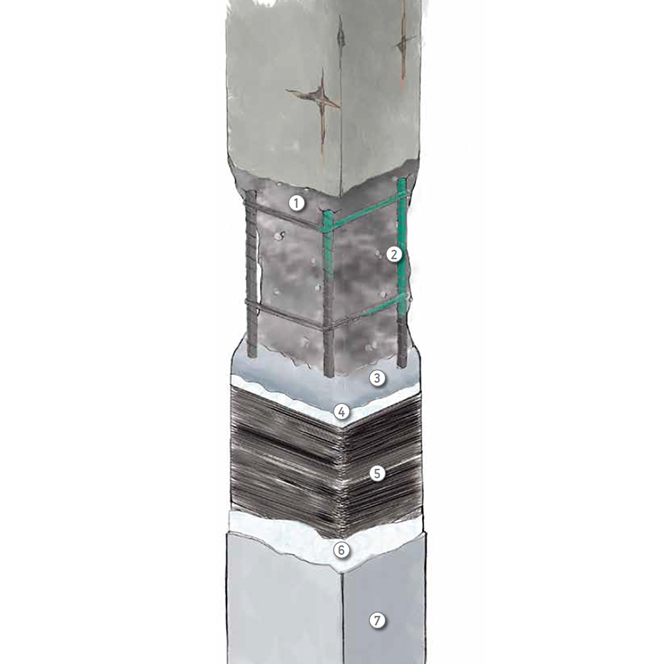

The Problem:The concrete strength of the The Solution:

|

|

|

The Problem:The pillar has deficiencies The Solution:

|

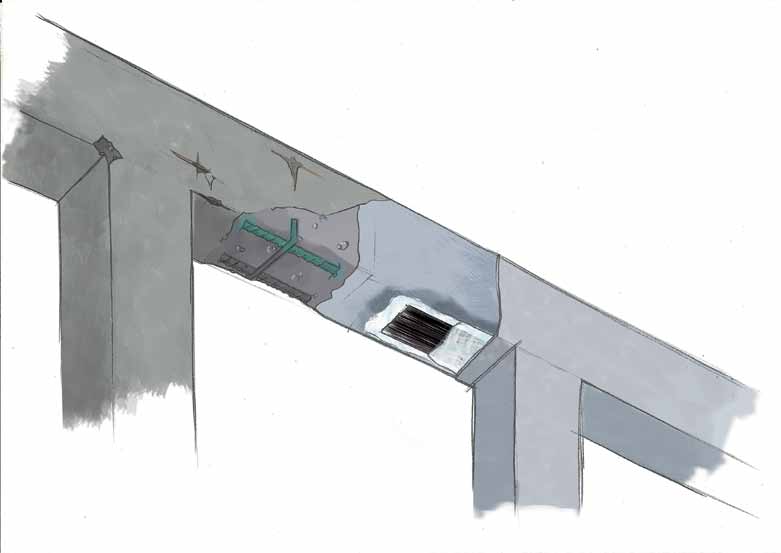

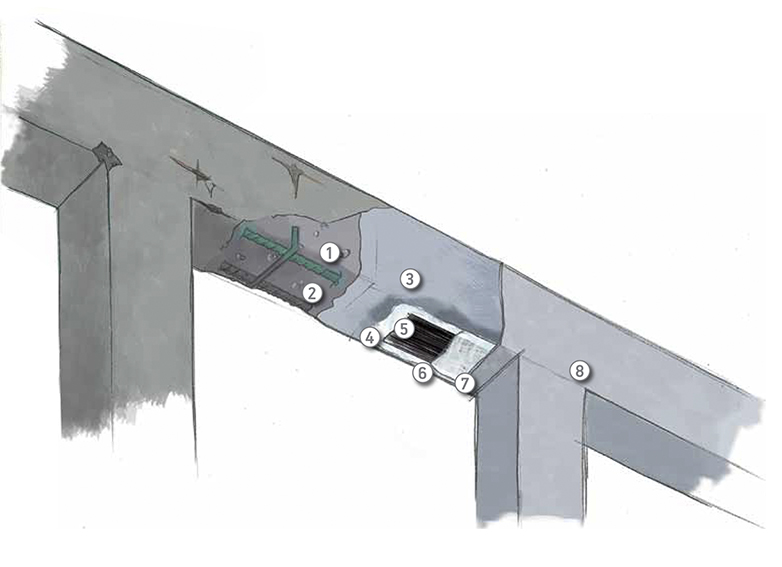

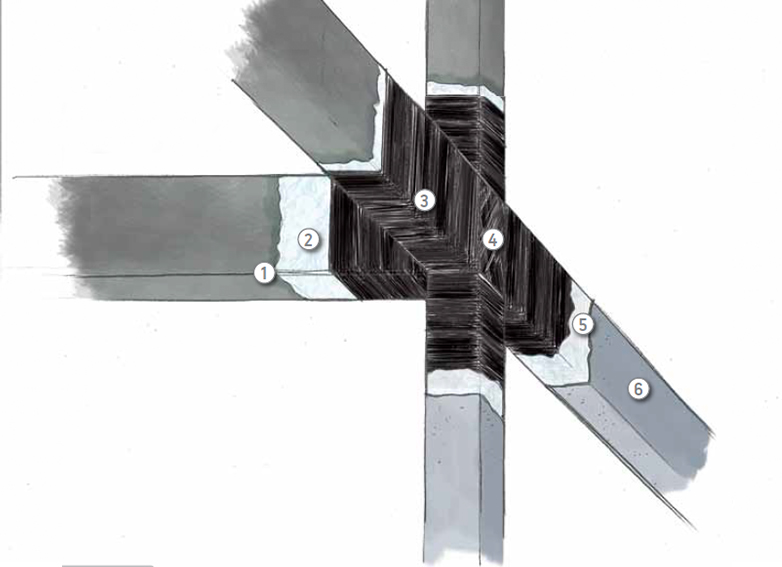

BEAM-PILLAR JUNCTION

|

The Problem:There is a need to increase the shear strength of the beam and pillar in the point of convergence, in The Solution:

|

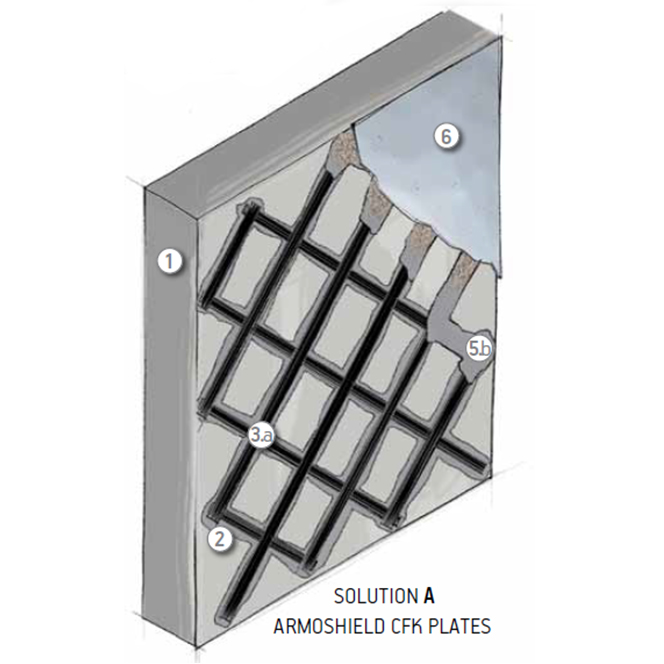

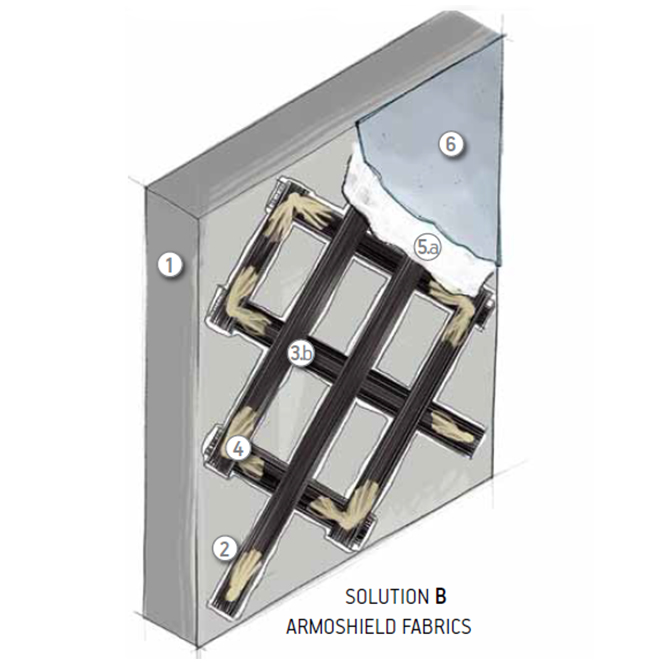

REINFORCED CONCRETE WALLS

|

|

The Problem:To improve the shear behaviour of reinforced concrete walls for seismic reinforcement or retrofitting Решението:

|