Description

Injection systems for embankment stabilization

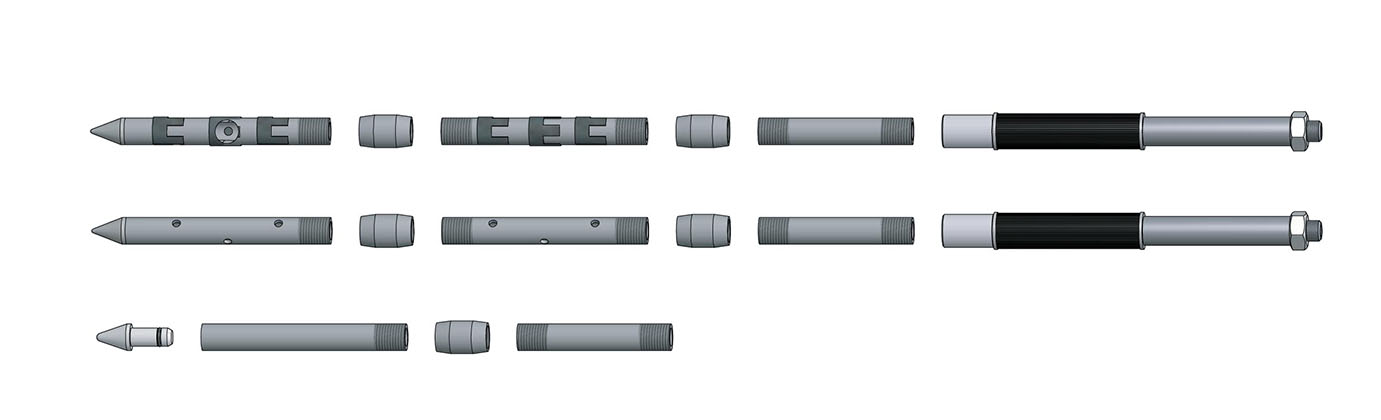

Steel pipes with a pointed tip and perforated injection holes in the walls are driven into the ground. If necessary, adapted extensions are used, which can also be with or without injection holes. This method is best suited for shallow and easy-to-penetrate soils. The maximum installation depth depends on the soil conditions, and it can reach 15 m. The injection material flows into the soil through the perforated holes. When using a detachable tip, the material leaks from the end of the drive packer. In order to inject under the foundation slab, holes are pre-drilled in it. Packers with a coupling sleeve are used for sealing injection.

|

Benefits

Purpose

|

Method of use

- Determine the scope of work with specialists in planning, geotechnics, etc.

- Note the location of the holes on the plate under which it will be injected, according to the developed concept

- Drill holes in the plate

- Insert the injection packers through the holes in the soil to a predetermined depth

- When injecting under a concrete slab, first wedge the steel packers into it

- Install a connection system to the drive packers

- Inject with the selected material

- After the injection is completed, remove the packers and the injection system

- Seal the holes drilled in the plate with a suitable material

Information

Soil injection in Germany requires approval from the Groundwater Control Service. Before starting the injection work, make sure that the provisions of the relevant local law are observed.

Injection machines

Stop pump SP-20-B

The SP-20-B scroll pump has a versatile application and high power in combination with compact dimensions. A control device controls the flow rate of the pump in the range from zero to maximum feed rate. Using an extension cord, the control device can be attached to the end of the material hose and connected to the machine so that the operator can react immediately, avoiding the creation of unwanted high pressure. In addition, the SP-20-B can be equipped with an attachable mixing device and a stand for pouring the material.

|

Benefits

|

|