Description

PROJECT: Spartak Swimming Complex, Sofia

CONTRACTOR: BILDCOM BG Ltd.

WORK TYPE: Structural restoration and protection of a concrete structure

The Spartak Swimming Complex in Sofia is an iconic venue for sports and recreation with a long-standing history. The complex is a popular destination for both professional athletes and swimming enthusiasts. Among its facilities is an outdoor pool with diving towers that required major renovation.

|

|

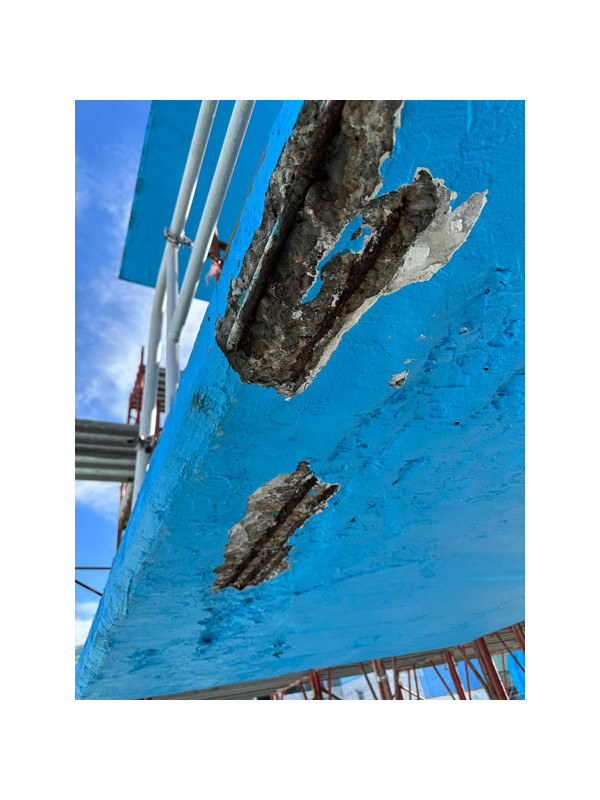

Challenges in Restoring the Concrete Structure

The project involved addressing multiple issues with the concrete structure of the diving tower, commonly seen in facilities of this type:

- Segregated concrete

- Corroded reinforcement

- Crumbling concrete sections

These problems required a comprehensive approach and the implementation of the best, long-lasting solution. High-tech materials designed for the repair and protection of bridge structures, hydraulic, and marine facilities were used for the successful restoration of the towers.

|

|

Products and Technologies Used

To successfully complete the repair, the following products, provided by our company, were used:

- DRACOSTEEL: Before repairing the concrete structure, the steel reinforcement exposed to atmospheric conditions was treated with DRACOSTEEL to restore alkalinity and protect against corrosion. Once cured, DRACOSTEEL is completely impermeable to water, fog, gases, and atmospheric conditions, ensuring excellent adhesion between the treated reinforcement and the subsequent restoration with FLUECO repair mortars.

- FLUECO 80 T Fiber: For the reconstruction and structural restoration of the concrete coating damaged by reinforcement corrosion, a high-strength repair mortar with fibers, FLUECO 80 T Fiber, was used. The repair mortar is reinforced with polymer fibers with a microstructural effect and flexible, inorganic, alkali-resistant fibers made of stainless steel. FLUECO 80 T FIBER is completely waterproof, resistant to freeze-thaw cycles, and is not affected by carbonation.

- CONCRETE FINISHER 2: To smooth the concrete surfaces and achieve a finished appearance, CONCRETE FINISHER 2, a thin smoothing layer, was used. It has exceptional chemical resistance to environmental pollutants, contact with sulfates, seawater, de-icing salts, sodium and calcium chloride, oils, freeze-thaw cycles, and more.

- ACRIPRIMER and ACRIPAINT: To protect the structures from carbonation and create a barrier against the penetration of carbon dioxide into the concrete, the structure was treated with a primer, ACRIPRIMER, followed by an acrylic paint, ACRIPAINT. This final step in the repair of the concrete jumping tower provides long-lasting protection and an aesthetic appearance of the surface.

- BITUMFLEX COLOR: For the finishing layer of the steps and springboards, BITUMFLEX COLOR, an elastomeric waterproofing coating with a colored finish, was used for additional protection and aesthetics. The product makes the surface more resistant to wear, UV rays, and chemical attack and is very suitable for pedestrian traffic.

|

|

Results of the Concrete Structure Repair

After the successful completion of the repair work, the jumping towers were fully restored and ready for operation. The achieved results include:

- Stability and safety of the structure

- Durable and aesthetic surface

- Reliable protection against corrosion and mechanical impacts

This project demonstrates how the symbiosis between understanding the problem and the client's needs and a professional approach in applying high-tech materials can ensure durability and high standards in the renovation of sports infrastructure.

|

|