Synthetic (polypropylene) fiber reinforcement replaces steel in concrete

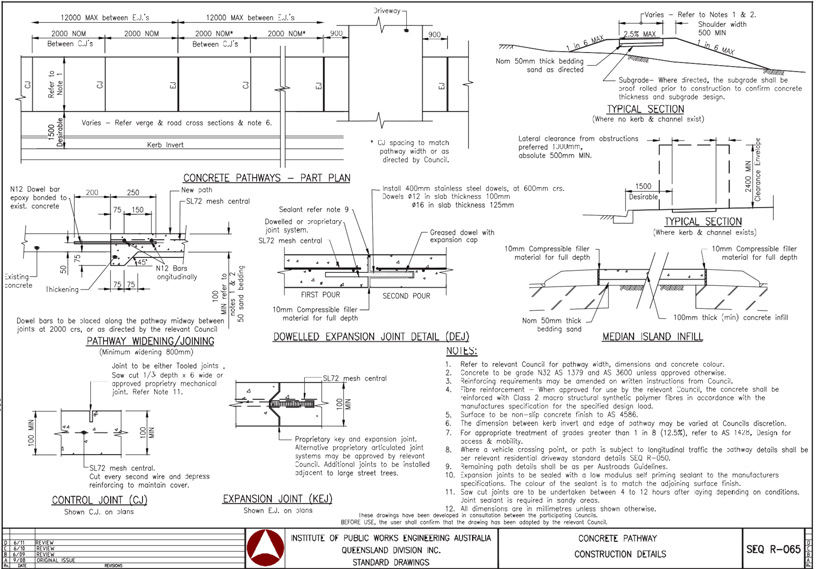

Australian Standard 3727 - Guide to the Construction of Concrete Pavements in Residential Areas specifies the requirements for the reinforcement of concrete pavements in the residential sector.

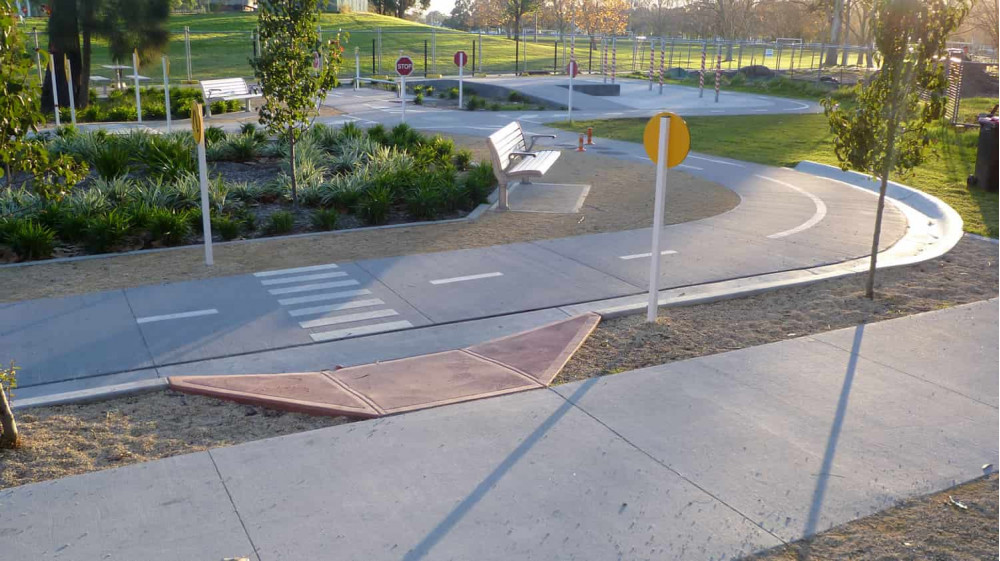

Step 1. Preparation of the soil bed

The bed is the natural soil on which the concrete pavement structure will be built. The top layer of soil containing grass, roots and other plant material should be removed.

Step 2. Preparation of the base

The base is the layer on which the concrete pavement will be built. The base must be smooth, level and well compacted, providing uniform support for the flooring.

Step 3. Considering the need to build drainage

When constructing the concrete pavement, the need for a drainage system to collect surface rainwater or from another source must be assessed. These waters must be led away from the pavement to a point specified in the pavement construction project.

Step 4. Determine the concrete type and BarChip® fiber dosage using the table on the opposite page.

Step 5. Order concrete

Order concrete from the nearest manufacturer that produces concrete with BarChip® reinforcing fibers

Step 6. Laying and finishing the concrete

Place and finish the concrete surface according to the existing recommendations and finishing guide.

Step 7. Ensuring suitable conditions for ripening (bonding) of the concrete

Provide suitable conditions for the maturation (bonding) of the concrete according to the existing rules (use of surface protection by laying a special product preventing the rapid evaporation of water, curing, moistening, etc.).

Table 1 shows typical concrete slab thicknesses (on resilient base), concrete grade, joint spacing and reinforcement requirement for residential pavement construction. (according to Australian Standard AS3727)

Table 1: typical specification for concrete pavements for use in residential construction. Source: AS3727 (Australian Specification)

| Traffic intensity | Minimum plate thickness mm | Minimum grade of concrete | Alternative 1 unreinforced | Alternative 2 | Alternative 3 | |||

| Maximum distance between joints m | Minimum reinforcing mesh | Maximum distance between joints m | Minimum reinforcing mesh | Maximum distance between joints m | Minimum reinforcing mesh | |||

| Pedestrians and bicycles | 75 | B20 | 2 | - | - | - | - | - |

| Light (cars) | 100 | B20 | 2 | - | 3 | F52 | 6 | F62 |

| Medium (cars) | 150 | B20 | 2 | - | 4 | F52 | 6 | F62 |

Table 2 shows a specification for the equivalent reinforcement of residential floors with BarChip Macro fibers. Based on extensive (standard) beam testing, independent engineers have calculated the amount of BarChip Macro fiber that needs to be dosed to meet the requirements to achieve equivalent reinforcement strength as set out in Australian Standard 3727 - Residential Flooring Guide .

Table 2: Typical specification with BarChip Macro42 fibers for reinforcing concrete pavements applied in residential construction.

| Traffic intensity | Minimum thickness of concrete pavement (mm) | Concrete grade | Maximum distance between control joints in concrete pavement (m) | BarChip Macro dosing Kg/m3 |

| Pedestrian only | 75 | N20 | 3 | 3.5 |

| Light duty - cars only | 100 | N20 | 4 | 3.0 |

| Medium load - light trucks | 150 | N32 (up to 1km distance from the seashore) | 5 | 3.0 |

All site preparation, base preparation, formwork, joints and concrete care operations shall be carried out in accordance with the requirements of AS 3727.

Light traffic - unrestricted movement of vehicles with a gross weight not exceeding 3 tons.

Average traffic – unrestricted movement of vehicles with a gross weight not exceeding 10 t, including frequency of operation by heavier vehicles, not exceeding the legally established requirements for the corresponding load values from the tires, wheels and axles.

Class II BarChip Macrosynthetic Fibers is a fertilizer for use in concrete for roads and streets (IPWEAQ).