Description

Cement-based systems for volumetric reconstruction and for restoration of concrete, reinforced concrete and pre-stressed reinforced concrete structures even in vertical and overhead positions.

Anti-corrosion treatment for reinforcing bars

DRACOSTEELPassivating, re-alkalizing solution for the treatment of reinforcing bars, for protection against corrosion. DRACOSTEEL is applied with a brush on the reinforcing bars of reinforced concrete. It is ideal for corrosion protection and for restoring the alkalinity of steel reinforcement, just before repairing the concrete structure with FLUECO and CONCRETE FINISHER products. Consumption: 100 g / m. reinforcement 8 mm. (2 mm thick, in 2 layers) |

Cement-based systems for volumetric reconstruction and for restoration of concrete, reinforced concrete and pre-stressed reinforced concrete structures even in vertical and overhead positions

FLUECO 80 TThixotropic, fibre-reinforced cement mortar with shrinkage compensation The features of FLUECO 80 T ensure to make structural restoration works of structures exposed to high chemical-physical and environmental attacks. Ideal for the renovation and thick lift of hydraulic works, viaducts, pillars and canalisation works. It is applied by trowel or by spraying. Consumption: approx.19 kg/m² per cm of thickness |

|

FLUECO 80 T2Two-component thixotropic fibre-reinforced mortar with low elastic modulus and shrinkage compensation The features of FLUECO 80 T2 ensure to make structural restoration works of structures exposed to high chemical-physical and environmental attacks. Ideal for repairing even precast structures subject to repeated stress or deformation, for repairing beams, pillars, floor slabs and reinforced concrete walls, and for restoring hydraulic works, viaducts and galleries, even on structures in contact with seawater. |

|

|

FLUECO 80 T FIBERTHIXOTROPIC, FIBRE-REINFORCED CEMENT MORTAR with shrinkage compensation FLUECO 80 T FIBER is a one-component, pre-blended cement-based mortar that is fibre-reinforced with polymer fibres with microstructural activity and fibre-reinforced with inorganic fibres being alkali resistant, stainless and flexible, to be mixed with water to obtain shrinkage-compensated thixotropic mixes. FLUECO 80 T FIBER develops high initial and final mechanical strength. It is waterproof and impermeable to carbon dioxide, durable |

RESTORE WITH POURABLE MORTARS AND CEMENT-BASED BINDERS

FLUECO 80 C FLOWFIBERSuper-fluid pre-mixed mortar , fibre-reinforced , |

Fluid expansive cement-based systems and grouts for anchoring

and grouting by the pouring of structures and machines

FLUECO 75Fluid expansive mortar for precision anchoring of machinery and structural elements The features of FLUECO 75 ensure to make precision anchoring works by pouring in thicknesses up to 10 cm. Ideal for maintenance and fast restoration works of infrastructures, bridges, viaducts and concrete structures in general, under high stress. |

|

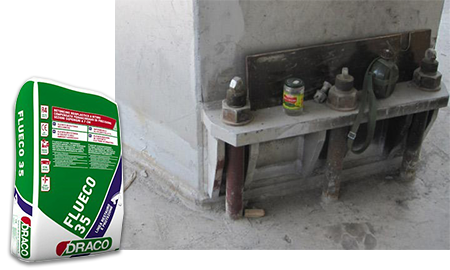

FLUECO 35Expansive shrinkage-compensated grout for precision anchoring The features of FLUECO 35 ensure to make precision anchoring works by pouring. It is also applied within formwork for grouting of reinforced concrete precast elements and metal frameworks, pins and rebars, for anchoring foundation slabs containing metal frameworks, and machines also subject to motion and vibrations. |

|

|

FLUECO 77 CABLEProduct for preparation of injection solution for protection of steel ropes and rods from the phenomenon of "stress corrosion". The solution for injection, obtained with FLUECO 77 CABLE, is extremely fluid with excellent early and ultimate tensile strength, compensated shrinkage, without water separation, pumpable, waterproof and long-lasting, with excellent adhesion to both steel and concrete.

|

Performances of mortars and grouts for anchoring as per UNI EN 1504-6

| FLUECO 75 | FLUECO 35 | |

| Classes as per 1504-3 standard | R4 | R4 |

| Maximum diameter of the aggregate (mm) | 2,5 | 5 |

| Apparent bulk density as per EN 12190 (kg/m3) | 2290 | 2300 |

| Mix water (%) | 16 | 13 - 14 |

| Application temperature (°C) | от +5 до +35 | от +5 до +35 |

| Pot life (20°C - U.R. 50%) | 60’ min. | 30’ min. |

| Compressive strength 28 days (MPa) | 80 | 70 |

| Flexural strength 28 days (MPa) | 11 | 12 |

| Compressive modulus of elasticity 28 days (GPa) | 30 | 30 |

| Bond strength on concrete as per EN 1766 (MPa) | > 2 | > 2 |

| Pull-out strength - EN 1881 (mm) | U = 0,04 A = 0,04 |

U = 0,03 A = 0,03 |

| Maximum thickness per layer (cm) | 10 | 20 |

| Consumption (approx. kg/m³) | 1950 | 2100 |